An excellent general-purpose material, TIVAR 1000 (natural) is a cost-effective solution for food handling problems, and meets FDA, USDA and 3-A Dairy guidelines for food processing and handling. Quadrant also offers custom colors compounded with FDA/USDA approved pigments, which meet FDA and USDA guidelines for food processing and handling. Whether your business is grain, pharmaceuticals, pizza dough or frozen poultry, TIVAR material will reliably move your materials and products.

TIVAR® is the brand name of Quadrant Engineering Plastic Products for its extensive range of virgin, partially reprocessed, colored or modified Ultra High Molecular Weight Polyethylene stock shapes, manufactured by compression moulding or extrusion.

Quadrant Engineering Plastic Products focuses on innovation by modification of TIVAR 1000 standard materials in order to meet specific market requirements.

TIVAR 1000 comes in natural and custom colors, and is available in oversize sheets as well as three standard sheet sizes:

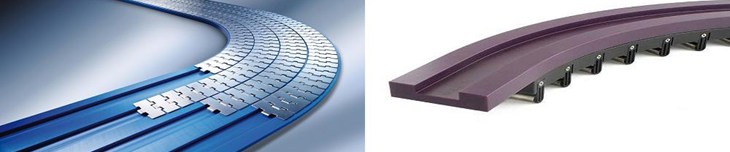

With its built in dry lubricant and 80% COF reduction, TIVAR® HPV was developed specifically for use in today's most demanding production environments experiencing; high speeds, high temperatures, high friction,high loads and aggressive cleaning agents. TIVAR® HPV materials and finished parts offer reduced friction, near zero level "slip stick," and a LPV value 18-35% higher (more slick) than competitive materials. The superior sliding performance of Quadrant TIVAR® HPV reduces friction of components against a mating partner while also better protecting parts from wear. Components made with TIVAR® HPV show improved sliding behavior and high wear and abrasion resistance at key touch points in conveyor systems.

TIVAR® HPV is a cost-effective, FDA approved solution for preventing excessive wear and deformation of parts to support the longest possible lifecycle in conveyors, directly contributing to time in use and safety benefits.